Phinna

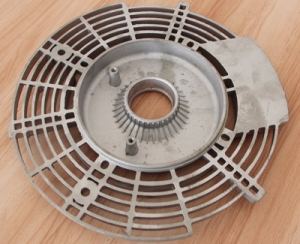

Engine Cover Die Casting Mould

Aluminium Alloy Die Casting Mold

Part: Aluminium Alloy Die Casting Mold

Mold cavities: 1,2 or multipe

Mold Material: SKD61,H13, Dievar, 8407 etc

Generator Cover Die Casting Mold

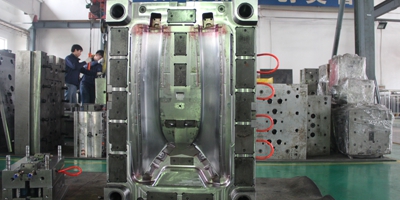

Control Housing Aluminium Die Casting Mold

Part: Control Housing Aluminium Die Casting Mold

Mold cavities: 1

Mold Material: 8407

Mold Shots: 80,000pcs

Aluminium heat sink die casting mold

Zink alloy flange base die casting mold

Plastic Injection Precision Mould

1) experience: From 2003 to now on, we have over 10 years’ rich experience on plastic injection precision mould making.

2) precision: at least to 0.02mm

3) mould life: 1 million - 2 million shots can be ensured

4) mould material: we choose good material like 2312, 2344, S316, 738 to guarantee the quality

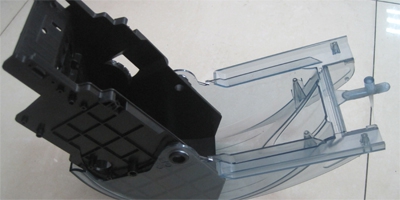

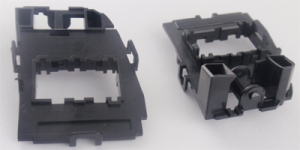

Automotive precision plastic injection mould

1)Usage: automotive precision parts

2)Mould cavity: we choose 1*1,1*2,1*4 or other cavities according to the corresponding automotive precision parts

3)Mould base:LKM, HASCO etc.

4)Moud type: two plates mould, three plates mould, hot runner mould etc.

Precision plastic injection mould

1)Precision plastic injection mould material: 718 718H 2738 2316 2344 S136 etc.

2)Precision plastic injection mould designing: we have about 20 skilled mould engineers. All of them are good at Pro-e, UG, CAD, SolidWork, CATIA.

3)Trial time: within 30 days after mould drawing confirmed

4)Packing: wooden cases

5)Mould life: 500,000 shots - 1 million shots

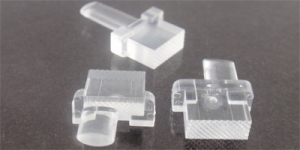

Electrical precise mould

1)parts precision:0.02mm

2) mould material: P20 718 718H 2738 2312 S136 etc.

3) electrical parts material: ABS,PP,PA,PA6,PA66,PC,PS,PE and so on

4) mould life: within 30 days after mould drawing confirmation

In China,we can make standard plastic injection moulds for you.

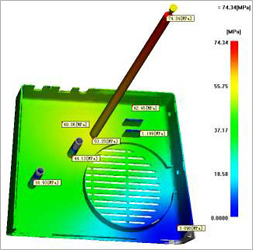

In China,we can make standard plastic injection moulds for you. For some big parts,or some parts with complex structure, in order to garantee the plastic material

For some big parts,or some parts with complex structure, in order to garantee the plastic material